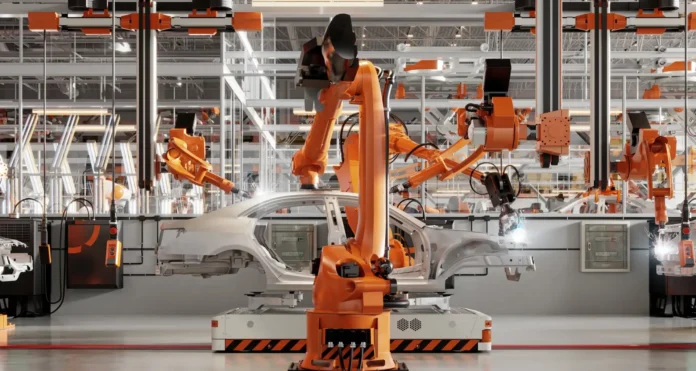

In the vast landscape of the automotive industry, the integration of robots into vehicle manufacturing, a key pillar of automated manufacturing, represents an undeniable revolution.

This transformation is not limited to the way vehicles are assembled, but profoundly alters the very fabric of automotive production, integrating robots into factories to streamline operations.

These industrial robots, with capabilities ranging from automated welding to in-mold assembly and labeling, have become indispensable in automotive factories worldwide. By optimizing processes and setting new standards in manufacturing efficiency, assembly line robots and automated assembly techniques are radically transforming the industry. Their use extends to a multitude of operations, both inside and outside the automotive factory, encompassing material movement,

part inspection, and precision painting. This highlights the versatility and essential role of robotic automation in contemporary automotive manufacturing .

The use of these robots goes far beyond improving operational efficiency or applying smart factory principles; it reflects the industry’s commitment to innovation and the constant pursuit of technological excellence, with assembly line robots at the forefront.

This move toward a more automated, efficient, and intelligent manufacturing landscape heralds a new era for automotive manufacturing. Smart factories and robotic manufacturing,

including automated assembly and assembly line robots, are playing a key role in the transformation and modernization of the industry.

The Evolution of Robotics in Automotive Manufacturing

The evolution of robotics in automotive manufacturing has been characterized by innovation and technological advancements, leading to a significant transformation of the industry.

While the concept of robots dates back to the early 20th century, the modern idea of robots in manufacturing took shape with the introduction of the Unimate robotic arm at a General Motors plant in 1961, marking the beginning of robotic manufacturing in the industrial sector.

The global automotive robotics market is expected to register a compound annual growth rate (CAGR) of around 12% between 2021 and 2027 , driven by several factors, including reduced labor costs, increased investments in production capacity, and the need to accelerate product launches. These trends highlight the growing importance of robotic assembly and assembly line robots in the automotive industry.

Types of robots and their applications

Automotive manufacturing uses two main types of robots: traditional “hard” robotics, used for repetitive tasks, and collaborative robots (cobots), which work in tandem with humans. This approach demonstrates the

industry’s adaptability and commitment to improving efficiency and safety. These robots are deployed for a variety of tasks, including assembly, welding, material handling, and more, demonstrating their versatility and the importance of robotic technology for innovation and productivity in the automotive industry.

Major robotic innovations redefining automotive manufacturing

The significant impact of robotics in the automotive manufacturing industry is evident in significant advances that have reshaped

production processes, increased efficiency, and improved quality. These advances are divided into different application categories, each playing a distinct role in the manufacturing process:

- Cobots : Cobots, or collaborative robots, have revolutionized production lines by integrating human cognitive abilities with the precision of machines. They play a crucial role in tasks requiring meticulous handling and complex assembly, thus enhancing the adaptability and flexibility of the production line.

- Robotic Painting and Welding : Robotic painting significantly reduces material waste while ensuring uniform coverage, while robotic welding improves productivity and ensures strong, clean welds on various vehicle components.

- Handling and quality control : To ensure the timely delivery of parts to the assembly line, robots are used for efficient material handling. Robots equipped with sophisticated vision systems can perform precise quality control, detecting even the smallest defects and ensuring that each component meets rigorous standards. This precision helps reduce production times and improve the overall quality of the automotive manufacturing process during operations such as component transfer, machine setup, and complex cutting and trimming procedures.

These robotic applications highlight the shift towards smarter, more flexible and efficient manufacturing processes, setting new standards for quality and productivity in the automotive industry through the integration of assembly robots and assembly lines.

The impact of robotics on the economy and

productivity

The impact of robotics on economics and productivity in automotive manufacturing is multifaceted, encompassing both significant advancements and challenges, as evidenced by the widespread adoption of assembly robots and

assembly line robots.

Positive points

- Quality and Consistency : Robotics ensures high precision and reproducibility in manufacturing, resulting in consistent product quality.

- Productivity and efficiency : Robots can operate 24/7 with an accuracy of up to 0.5 mm, significantly increasing the productivity and efficiency of control systems. This level of precision and efficiency is characteristic of robotic assembly and the use of assembly line robots.

- Cost Reduction : Using robots helps reduce labor costs and overhead, thereby generating long-term savings.

- Workplace Safety : Robotics improves safety by taking over dangerous tasks and reducing workplace accidents.

Challenges

Initial Investment and Maintenance : High initial costs and the need for sophisticated maintenance require expertise, which can lead to increased ongoing expenses.

Impact on the workforce : The introduction of robotics has led to job displacement within manufacturing and other sectors, highlighting the critical need for reskilling. This challenge underscores the transformative impact of assembly robots and assembly line robots.

Productivity paradox : Despite increasing robot density, some industries are experiencing lower productivity gains, highlighting a complex relationship between automation, robotic assembly, and economic outcomes.

Meeting the challenges of robotics in automotive manufacturing

Addressing the challenges of robotics in automotive manufacturing requires a multifaceted approach focused on cost management, workforce development, and technological adaptability.

Cost management and return on investment

High initial investment and ongoing maintenance costs represent major obstacles. To mitigate these, it is strategic to leverage economies of scale, seek government incentives, and invest in modular robotic systems that offer increased flexibility and lower long-term costs. A prudent approach to robotic assembly is

essential. Ensuring sustained production volumes and sales levels is imperative to recoup the initial investment. This requires strategic market analysis and an agile response to automotive industry trends to maintain competitiveness.

Workforce Development

Embracing automation requires a skilled workforce familiar with robotics, software development, and artificial intelligence. Employers must invest in comprehensive training programs and create an environment where

workers don’t fear being replaced by robots . They must also partner with educational institutions to fill

skills gaps and prepare a new generation of robotics technicians and robotics programming experts.

Promoting diversity and inclusion within the organization, as well as collaborating with businesses and educational institutions, can improve recruitment strategies and prepare the workforce for the changing

demands of the automotive industry, ensuring a strong talent pool for robotic assembly.

Technological adaptability

To overcome the limitations of current robotic technologies, it is imperative to invest in research and development to design more adaptable and easily repurposed robots. This includes improving the robots’ ability to adapt to third-party parts and variable control parameters without incurring significant additional costs, which is a key aspect of the evolution of robotic assembly. The new safety risks associated with advanced robotics require the development of new procedures and training to ensure a safe and regulatory-compliant work environment

, a critical step for the integration of robotic assembly into industries.

Future Trends in Automotive Robotics

Exploring the automotive robotics horizon reveals a dynamic and transformative landscape, characterized by several key trends poised to redefine the industry through innovative robotic assembly techniques.

- Integration of advanced technologies :

- Artificial intelligence and machine learning: These technologies improve decision-making processes, automate complex operations, and provide insights from large data sets, increasing the efficiency and adaptability of robots in automotive manufacturing through advanced robotic assembly methods.

- Autonomous Vehicles: Thanks to advances in AI, sensor technology, and connectivity, autonomous vehicles are moving from concept to reality and promise to revolutionize the automotive industry by improving safety, efficiency, and the overall driving experience.

- Collaborative efforts and sustainability :

- Sustainable manufacturing: The adoption of green energy, recycling, and the use of sustainable materials in 3D printing processes demonstrate the desire to adopt sustainable practices in the automotive manufacturing industry. This trend is not only environmentally friendly, but also meets consumer expectations for eco-friendly products and processes.

- Collaborative robots continue to gain importance, designed to complement human workers by increasing workplace efficiency, safety, and flexibility.

- Emerging robotic applications :

- Soft robotics and swarm robotics : These innovative approaches, which exploit soft materials and coordinated multi-robot systems, expand the capabilities of robotics in automotive manufacturing. They enable robots to perform tasks with a level of finesse and cooperation previously unattainable, opening new avenues for the automation and efficiency of robotic assembly.

Conclusion

This exploration of the impact of robots in automotive manufacturing allowed us to see how robotic automation has not only revolutionized vehicle assembly but also set new standards for

efficiency, quality, and innovation in manufacturing. The evolution of traditional manufacturing techniques toward the integration of robots in the automotive industry illustrates a dynamic trajectory where technology and sustainability are converging to redefine industry standards. By examining the roles of collaborative robots,

the importance of robotic welding and painting, and critically analyzing material handling and quality control, our discussion highlighted the diverse contributions of robotics to automotive manufacturing.

Future trends in automotive robotics, such as the rise of artificial intelligence, the advent of autonomous vehicles, and the focus on sustainability, are paving the way for a dynamic horizon for the

automotive manufacturing industry. Reflecting on the shared insights, it becomes clear that the journey of robotics in automotive production is not just about automation, but also about leading change, fostering innovation, and preparing for a future where robotics and human ingenuity collectively propel the industry forward.

FAQ

Robots and automation technologies, such as assembly robots and assembly line robots, are revolutionizing the manufacturing industry by improving efficiency, speeding up production, and reducing costs. These automated systems are capable of handling a variety of tasks, freeing up employees to focus on more complex tasks.

In the automotive manufacturing industry, robots, particularly those used in robotic assembly and assembly lines, play a

vital role in automating repetitive and precision-demanding tasks. They are used on car assembly lines to

precisely position parts, apply adhesives, and perform complex assembly operations, ensuring high-quality production.

Artificial intelligence is poised to radically transform the automotive industry by introducing fully autonomous vehicles, enabling

predictive maintenance, and implementing advanced safety features. AI technologies will enable cars to deliver personalized driving experiences, adapting to each user’s unique preferences.

The automotive industry is undergoing a transformation thanks to the adoption of cutting-edge technologies. Automakers are using data and

innovative technologies for a variety of purposes, including vehicle simulation testing, improving operational efficiency, predictive maintenance, and developing autonomous vehicles. These advancements

significantly improve passenger and vehicle safety.